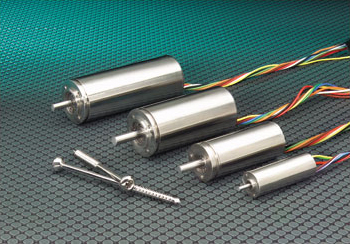

BLDC motors employ electronic commutation instead of mechanical commutation to convert direct currents into alternating currents. While brushed DC motors have windings on the armature connected to commutators at one end, brushless DC motors have transistors arranged in a specific configuration that applies pulses to a coil, causing the magnet to spin. Thanks to this and other benefits BLDC motors offer, they’re well suited for motion-control, positioning and actuation systems. Custom BLDC motor manufacturers build the devices for use with linear motors, servomotors, CNC machine tool feed drives, extruder drive motors, and industrial robots with actuators.

BLDC motors employ electronic commutation instead of mechanical commutation to convert direct currents into alternating currents. While brushed DC motors have windings on the armature connected to commutators at one end, brushless DC motors have transistors arranged in a specific configuration that applies pulses to a coil, causing the magnet to spin. Thanks to this and other benefits BLDC motors offer, they’re well suited for motion-control, positioning and actuation systems. Custom BLDC motor manufacturers build the devices for use with linear motors, servomotors, CNC machine tool feed drives, extruder drive motors, and industrial robots with actuators.

Benefits of BLDC Motors

- Great accuracy

- Magnets are within the rotor

- Superior efficiency

- Smooth, controlled torque

- Great torque-to-size ratio

- Higher speed ranges

- High-speed operation

- Longer lifespan because of the lack of friction and electrical losses

- Ease of maintenance because brushes and mechanical commutators aren’t present

- Little to no maintenance

- High power-to-size ratio

- High acceleration and deceleration capabilities

- Reduced electromagnetic interference because there aren’t brushes to produce ionizing spikes

- Quieter operation

- Available in small sizes for use in compact locations

- Stay cooler and dissipates heat better

Precision from BLDC Motors in Industrial Positioning and Linear Actuation Systems

Brushless servomotors are a key component in assembly robots that precisely position tools and parts during the manufacturing process. When used in linear motors, which exhibit linear motions without a transmission system, equipment is more responsive and accurate. The motors have a slotted stator with magnetic teeth, as well as a moving actuator. The stator’s poles are laid in the direction of travel.

BLDC linear servomotors are made up of a moving actuator with coil windings and permanent magnets, and a slotted stator with magnetic teeth. Creating the linear motion is a matter of the motor controller exciting the actuator’s coil windings, which causes the magnetic fields to interact. In linear actuation and industrial positioning systems, BLDC motors also offer the advantages of no hysteresis, mechanical connections or pitch cyclical errors.

The Use of Custom BLDC Motors in Motion Control Systems

Because of their compact nature, brushless DC motors perform effectively in spindle drives, fans, pumps and applications that require adjustable or variable speeds. To provide variable speed responses, brushless motors in motion control systems have an electromechanical system with a rotor position feedback sensor and electronic motion controller.

In manufacturing applications, the motors are simple to automate for remote controls and have good torque-related speed responses. Custom BLDC motors are also designed to have good thermal characteristics.

When used in servomotors for precision motion control, positioning, or displacement, brushless DC motors use a closed-loop control system so movements are stable and controllable. Unlike brushed DC stepper motors in servomotors with open loop controls, brushless motors in closed-loop control systems don’t produce torque pulsations. This characteristic improves accuracy and ensures stable, reliable operations and dynamic responses, even when there are variations in motor parameters or load inertia.

Examples of BLDC Motor Applications

- Aerospace: Brushless DC motor manufacturers design motors to withstand high shock loads and extreme temperatures of up to 200°C. They’re also ideal for sensitive applications. When compared to nitro-, or gasoline-, powered engines, BLDC motors produce more torque and have a greater peak RPM. NASA prefers brushless DC motors over brushed motors for space environments because of their reliability, efficiency and reduced electromagnetic interference.

- Electric vehicles: When used in electric and hybrid vehicles, BLDC motors promote efficiency as they can operate at unity power factor. Brushless motors make rotor cooling simpler and generate less rotor heat. The motor’s response is quick and its components may have fully integrated drive solutions.

- HVAC: The use of brushless DC motors is a growing trend in the HVAC industry as manufacturers acknowledge the energy efficiencies they offer. Because the motors require less maintenance and have a longer lifespan than brushed motors, they may reduce costs related to energy consumption and HVAC repairs.

Sinotech specializes in designing and manufacturing custom BLDC motors for sensitive manufacturing applications. Our extensive motor catalog, 20-plus years of experience, team of experts, affordable costs, and close ties to the best factories in the Pacific Rim have made us a trusted source of motors and components. Contact Sinotech today to learn which BLDC motor is best for your manufacturing application.