Commutators and brushes are integral parts of motors. In a motor, the commutator is the part of the rotary electrical switch that moves. The other part of the rotary switch is a set of two or more brushes. The brushes conduct electrical currents between a rotating shaft and stationary wires. By understanding the role of commutators and brushes in motor design, you can make a more informed decision about the motor you choose for your application.

Commutators and brushes are integral parts of motors. In a motor, the commutator is the part of the rotary electrical switch that moves. The other part of the rotary switch is a set of two or more brushes. The brushes conduct electrical currents between a rotating shaft and stationary wires. By understanding the role of commutators and brushes in motor design, you can make a more informed decision about the motor you choose for your application.

Commutators and Brushes Working Together

For a gear motor or electric motor to work, the rotor’s coils must connect to complete the circuit and create a current. To achieve this connection, springs press metal brushes onto the commutator, which is connected to the shaft and armature windings. The commutator reverses the electric current in a winding as the shaft rotates. The brushes gradually shift the electrical current from one of the commutator’s contact bars to the next.

In a motor, the electric current in the armature produces a rotational force on the winding in the fixed magnetic field, causing the winding to turn.

Different types of brushes come into contact with the commutator in different ways and at different angles. The materials from which the brushes are made determine how the rotor can spin. Copper brushes, for example, may not be ideal for rotors that need to spin backwards because pieces of copper may embed into the different segments and cause damage. As the brushes wear down toward the commutator, they become smaller and thinner. Eventually, the brushes get so small that they need to be replaced.

Your Solution for Commutators and Brushes

Sinotech offers a variety of commutator styles and a full line of graphite and copper graphite brushes. Commutator styles include molded shell, large shell air gap, mica, expanded tang and industrial steel core commutators for automotive applications. Sinotech spin tests the commutators to ensure their endurance.

Sinotech tests its graphite and copper graphite brushes in actual motors to make sure they meet specified operating parameters. The brushes work well in automotive applications, battery-powered tools and fans.

Contact Sinotech to see which brushes and commutators are best for your application and learn about the other motor components available.

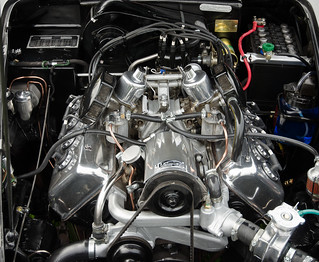

[Photo by Steve Glover via CC License]