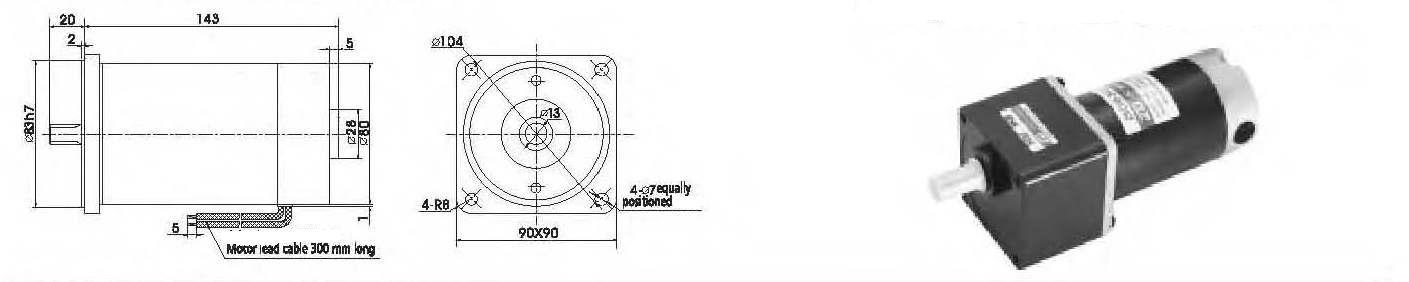

60W-120W 90mm DC Gearmotors

DC and AC Gear Motor Terms

- Axial movement: The movement at the ends of input and output shafts.

- Backlash: The output shaft’s rotational movement when the input shaft is stationary.

- Center distance: The distance between the center of the output and input shafts.

- Gear ratio: The input RPM divided by the desired output RPM.

- Input horsepower: The power that a prime mover applies to a reducer’s input shaft.

- Helical gears: Compact, efficient gears that you can use in perpendicular and non-parallel shafts. They can come with a 5:1 ratio per gear stage and can tolerate heavier loads than spur gears, but are less efficient.

- Mechanical rating: The maximum torque that a speed reducer transmits.

- Overhung load: The bending force in a shaft that’s resisted by the bearing and reducer shaft due to force applied to a reducer shaft’s right angles.

- Output horsepower: The power available at a reducer’s output shaft.

- Spur gears: Widely manufactured gears that are efficient and compact. Spur gears can come with a parallel shaft arrangement and a 10:1 ratio per gear stage. The gears don’t tolerate as much shock as worm gears and are noisier.

- Thermal rating: A speed reducer’s continuous transmission of maximum torque, based on its capacity to dispel heat.

- Torque: The force that rotates an object around an axis. In gear motors, torque is force multiplied by the radius of a pulley (the distance from the shaft’s centerline).

- Worm gears: Available in right-angle configurations, single-gear setups and 100:1. Worm gears are less efficient than other gear types, but are generally quieter and tolerate high shock loads.

It’s essential to choose the right AC or DC gear motor for your applications. If you need assistance with this process or need help understanding the various components, get in touch with Sinotech today.