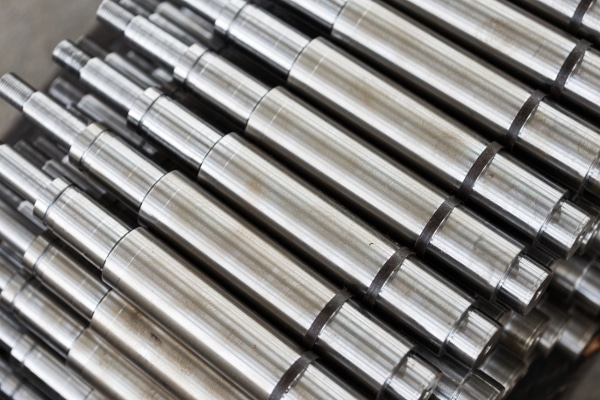

Shafts are a key component in most rotating equipment. Considering the best material for your electric motor shaft. There are several considerations: Cost and Material Deficiencies.

Most Common Shaft Material

Most motor manufacturers use SAE 1045 in either cold-rolled (CRS) or hot-rolled steel (HRS). Forged or normalized, C1045 is a medium carbon, medium tensile steel. This steel shows good strength, toughness and wear resistance.

Axles, bolts, forged connecting rods, crankshafts, torsion bars, light gears, guide rods etc use

Other materials include sulfurized SAE 1117, SAE 1137, SAE 1144, hot-rolled SAE 1035, and cold-rolled SAE 1018. A ground stock of any material is used on special CNC Swiss turning machines.

Advantages of CRS

Generally, the cold-rolled and sulfurized steels will increase costs approximately 15% more than HRS and will machine better. Machining trials need to be performed in order to justify the extra cost. Since all shaft-turning machines perform differently, there is no established material or machining practice.

Advantages of Hot-Rolled Steel

The hot-rolled plain carbon steel, on a cost-per-pound basis, is cheaper than cold-rolled sulfurized steel. But there are trade offs. The hot-rolled material has to be sized larger than cold-rolled because of the lack of outer diameter (OD) control in the rolling process.

Manufacturers of electric motors evaluate whether the larger-size and lower-material-cost hot-rolled bar stock is more or less costly than cold-rolled bar stock.

The hot-rolled material, by the very nature of its processing, has hard and soft spots, residual stresses, voids, and other material deficiencies, making it more difficult to machine. The problem with some high strength steels is the hardest part is only the outside layers, so when the shaft is machined down you will lose the strength.

Shaft Material Manufacturers

Here is a partial list of manufacturers of shaft blanks.

Related Topics

Here are some topics and pages on this website that are related to shaft material selection.

Machine Trials Needed in Selecting Shaft Material

Machine trials need to be conducted to decide the best option between CRS, HRS, non-sulfurized, and sulfurized materials. (Due to the difficulties with HRS, most motor manufacturers will use sulfurized CRS.)