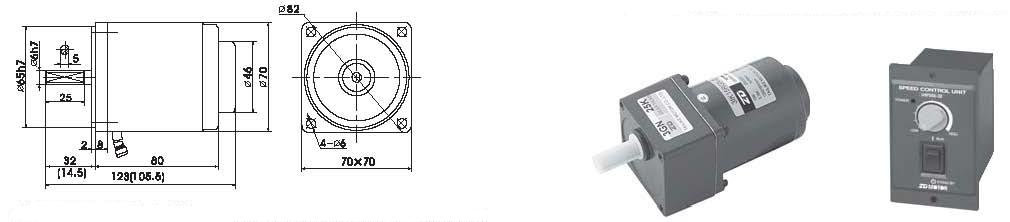

Adjustable Speed Motors

15 Watt 70mm

Ask an engineer to list the differences between AC gear motors and DC gear motors, and you can expect a quick, concise answer: AC motors are generally smaller, less expensive, lighter and more rugged than brushless DC motors. DC motors, on the other hand, are generally considered better for variable speed operations. Their improved speed control makes DC custom motors more expensive to purchase and maintain, generally.

Given enough time, the engineer might explain the technical aspects that differentiate these two gear motors. If speaking to a layperson, the engineer would explain that AC stands for alternating current, while DC stands for direct current. A more advanced audience might get information on the basic design of each gear motor – an AC gear motor typically features a rotor inside a stator with coils. In contrast, a brushless DC motor might have rotating armature windings with a stationary magnetic field.

AC Motor vs. DC Motor Advantages

If you’re reading about gear motors, you’re probably an engineer yourself, so let’s skip to what would interest designers like you: AC gear motor advantages, compared to their DC counterparts.

- AC gear motor design has advanced greatly in the last few years where an AC motor can offer as much or even more speed control as a brushless DC motor. Today’s AC motors can be regulated to within .1 percent of the desired speed.

- DC gear motors are still more expensive, on average. A big advantage of AC gear motors for manufacturers is their lower price. Today, an AC motor and drive together can cost the same as a DC micro motor.

- Because they typically require fewer repairs, an AC motor is better for potentially wet, hard-to-reach, or otherwise hazardous environments.

- Technological improvements have brought AC gear motors up to speed with DC motors. For instance, modern AC motors can provide full torque immediately, at startup. That was impossible just a few years ago.

AC Motor vs. DC Motor Industrial Applications

AC motors and DC motors find themselves in various applications across industries. Their industrial applications include:

| AC Motors | DC Motors |

|

|

Choosing the Right Motor for Your Needs

Even with all of these advantages, there are some situations that still demand a brushless DC motor or a high-performance AC motor. For one thing, engine cooling is crucial for long-term performance, so a premium-efficient or energy-efficient motor is recommended for adjustable-frequency drives. High starting loads and the demand for consistent horsepower while operating 150 percent above base speed are a few other applications that demand specialized motors.

The best way to determine which gear motor is right for you is to contact a custom motor manufacturer. At Sinotech, we don’t just supply motors; we provide solutions. Our expert consultation services are designed to help you navigate the selection process, considering all critical factors such as cost, performance, efficiency, and application-specific requirements. Our engineers and consultants have extensive experience in both AC and DC custom motor technologies. They are equipped to assess your needs, recommend the most suitable motor type, and even design custom motor solutions that perfectly fit your unique application.

Leveraging our deep understanding of motor technology and vast industry experience, Sinotech ensures that you receive not only the best motor for your application but also continuous support from design to delivery and beyond. Partnering with Sinotech means having a dedicated team committed to your project’s success, helping you make informed decisions that optimize performance and value.

Choosing between an AC and DC custom motor involves weighing various factors, but you don’t have to do it alone. Let Sinotech’s expertise guide you to the right motor solution, tailored to your specific needs and designed for optimum performance.