Without complex electronic control, synchronous motors are inherently constant-speed motors. They operate in absolute synchronism with line frequency. As with squirrel-cage induction motors, speed is determined by the number of pairs of poles and the line frequency.

Synchronous motors are available in subfractional self-excited sizes to high-horsepower direct-current excited industrial sizes. In the fractional horsepower range, most synchronous motors are used where precise constant speed is required. In high-horsepower industrial sizes, the synchronous motor provides two important functions. First, it is a highly efficient means of converting ac energy to work. Second, it can operate at leading or unity power factor and thereby provide power-factor correction.

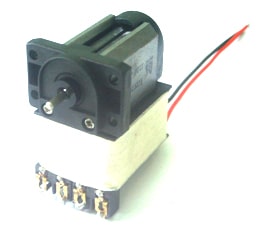

There are two major types of synchronous motors: nonexcited and direct-current excited.

Synchronous Motor

Synchronous Motor

Nonexcited Motors

- Manufactured in reluctance and hysteresis designs, these motors employ a self starting circuit and require no external excitation supply. Reluctance designs have ratings that range from sub fractional to about 30 hp. Sub fractional horsepower motors have low torque, and are generally used for instrumentation applications. Moderate torque, integral horsepower motors use squirrel- cage construction with toothed rotors. When used with an adjustable frequency power supply, all motors in the drive system can be controlled at exactly the same speed. The power supply frequency determines motor operating speed.

- Hysteresis motors are manufactured in sub fractional horsepower ratings, primarily as servomotors and timing motors. More expensive than the reluctance type, hysteresis motors are used where precise constant speed is required.

DC-excited Motors

Made in sizes larger than 1 hp, these motors require direct current supplied through slip rings for excitation. The direct current can be supplied from a separate source or from a DC generator directly connected to the motor shaft.

Synchronous motors, either single or polyphase, cannot start without being driven, or having their rotor connected in the form of a self-starting circuit. Since the field is rotating at synchronous speed, the motor must be accelerated before it can pull into sync. Accelerating from zero rpm requires slip until syncing is reached. Therefore, separate starting means must be employed.

In self-starting designs, fractional horsepower motors use methods common to induction motors (split phase, capacitor-start, and shaded pole). The electrical characteristics of these motors cause them to automatically switch to synchronous operation.

Although DC-excited motors have a squirrel-cage for starting, the inherent low starting torque and the need for a DC power source requires a starting system that provides full motor protection while starting, applies DC field excitation at the proper time, removes field excitation at rotor pullout, and protects the squirrel-cage winding against thermal damage under out-of-step conditions.

Sinotech Synchronous Motors are engineered in the U.S. and manufactured in China, Taiwan and Korea.