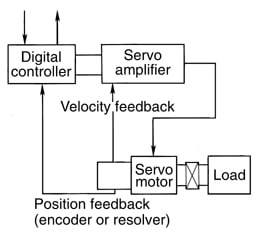

Servo motors are used in closed loop control systems in which work is the control variable, as in the illustrated figure. The digital servo motor controller directs operation of the servo motor by sending velocity command signals to the amplifier, which drives the servo motor. An integral feedback device (resolver) or devices (encoder and tachometer) are either incorporated within the servo motor or are remotely mounted, often on the load itself. These provide the servo motor’s position and velocity feedback that the controller compares to its programmed motion profile and uses to alter its velocity signal. Servo motors feature a motion profile, which is a set of instructions programmed into the controller that defines the servo motor operation in terms of time, position, and velocity. The ability of the servo motor to adjust to differences between the motion profile and feedback signals depends greatly upon the type of controls and servo motors used.

Typical DC Servo Motor system with either encoder or resolver feedback. Some older servo motor systems use a tachometer and encoder for feedback.

Three basic types of servo motors are used in modern servo systems: AC Servo Motors, based on induction motor designs; DC Servo Motors, based on DC motor designs; and AC Brushless Servo Motors, based on synchronous motor designs.

Sinotech can ensure excellent Servo Motors from China, Taiwan and Korea and is very price competitive. Sinotech Motors manufactures QS-9000 and ISO certified Servo Motor factories in China, Taiwan and Korea for over 15 years. Sinotech Motor sis dedicated to delivering servo motors from to you at lower prices but the same quality, service and terms as a domestic supplier.

Sinotech Servo Motors are engineered in the U.S. and manufactured in China, Taiwan and Korea.