Since 2003 Sinotech has been involved in the R&D and manufacturing of high-quality complex iron core motor laminations and lamination stacks. Our factory covers an area of 20000 square meters. Our staff consists of 70 skilled employees, overseen by our staff of 20 professional engineers.

Our focus is the manufacture of iron core motor laminations and lamination stacks for stators and rotor cores for car motors; tubular motors; home appliance motors; elevator motors; shaded pole motors; transformer cores; and, DC rotors. An estimated 70% of these products are exported to the international market, and 30% are sold to the U.S. domestic market.

Our robust tooling offers a low cost alternative to manufacturers with moderate to high volume lamination requirements. Our average lead time on tooling for lamination and lamination stacks ranges from 10-12 weeks. Carbide tooling is also an option with almost the same lead time as typical tool steel dies. In addition, with press capabilities of over 250 strokes per minute, and up to 440 tons of force, our prices are very competitive.

As a custom lamination manufacturer, we can supply custom motor laminations and lam stacks in all shapes and sizes. Our toolmakers are able to build and maintain a wide variety of production dies.

Our manufacturing operations utilize advanced production equipment from Hauser, Charmilles and Sodick for the production of progressive dies. We have over thirteen high speed stamping presses from Sumitomo, Aida and JDM ranging from 63 tons @ 150 to 400 SPM (strokes per minute) to 300 tons @160 to 350 SPM. Our stamping presses can accommodate dies with a maximum length of 2300mm. We have the capacity to process 30,000 tons of silicon sheet steel into motor laminations annually.

Types of Laminations

- Rotor Laminations

- Stator Laminations

- Notching Laminations

- Welding Laminations

- Segmented Stator Laminations

- Armature Laminations

- Transformer Laminations

- Trimmed Laminations

- Custom Laminations

- Stake Core Laminations

Tooling Options

- Progressive Dies

- Compound Dies

- Notching Dies

- Progressive Staking Dies

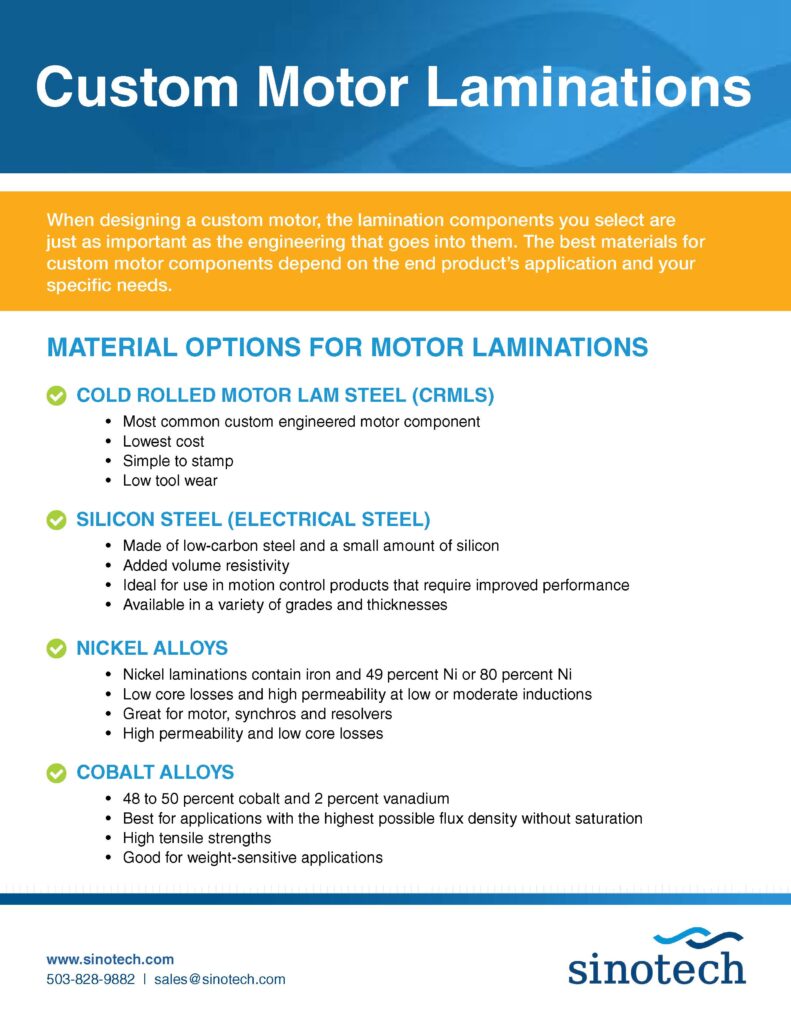

Laminate Materials

- Semi-Processed and Fully Processed Silicon Steel

- Cold Rolled Motor Lamination Steel

- Nomex

- M4 to M64 Electrical Grade Steels

- CO Thru C5 Insulative Coatings

Secondary Operations

- Annealing

- Stress Relief Annealing

- Stacking and welding.

Sinotech ensures excellent quality custom motor laminations and lamination stacks from China, Taiwan and Korea and is very price competitive in Cold Rolled Motor Lam Steel, Silicon Steel, Nickel Alloy, and Cobalt Alloy laminations. Sinotech has audited, qualified and worked with QS-9000 and ISO certified lamination factories in China, Taiwan and Korea for over 12 years. Sinotech is dedicated to delivering laminations from China, Taiwan and Korea to you at lower prices but the same quality, service and terms as a domestic supplier.

LAMINATION TUTORIAL

Few decisions in the design of an electric motor are as fundamental, or have as far reaching consequences as the selection of the material to be used in the rotor or stator motor laminations, which become lamination stacks. Motor output, heat rise, weight, and cost are only a few of the characteristics which are profoundly influenced by the selection of core material. ( The term motor is used loosely here to include generators, tachometers, resolvers, alternators, etc).

No one material is optimum (or even usable) for every application. As with all design decisions, trade offs must be made between cost, weight, size, and other factors. In addition, the processing of the laminations after fabrication can have a large influence on the performance of the unit being designed.

The criteria for material selection include cost, permeability, core losses, and saturation flux density. Permeability and core losses vary with the frequency of flux reversals (in Hz), and with flux density. In certain applications, the shape of the hysteresis curve becomes important. Each of the available materials is optimized for one or more of these properties, while being less than perfect in other areas. Custom laminations and custom lam stacks are often required.

Cold Rolled Motor Lam Steel (CRMLS)

Also called Cold Rolled Lamination Steel, this material is the lowest cost material for volume applications. In terms of tonnage, this is probably the most common material in use today. Ease of stamping and low tool wear help to contribute to the low cost of finished laminations. Carbon steel should be considered for applications where relatively high core losses are acceptable (D.C. pole pieces, low duty cycles, etc.) and low first cost of the end unit is of primary importance. This material is almost always annealed after stamping to develop optimum properties. This adds little to the cost when done in a continuous furnace, and allows an oxide coat to be added to the surface to provide interlaminar resistance. The heat treatment is somewhat critical, and the supplier should be consulted prior to specifying an annealing cycle. When properly annealed, modern grades of Lamination Steel have core losses rivaling the lower grades of silicon steel.

Silicon Steel (Electrical Steel)

When low carbon steel is alloyed with small quantities of silicon, the added volume resistivity helps to reduce eddy current losses in the core. Silicon steels are probably of the most use to designers of motion control products where the additional cost is justified by the increased performance. These steels are available in an array of grades and thicknesses so that the material may be tailored for various applications. The added silicon has a marked impact on the life of stamping tooling, and the surface insulation selected also affects die life. Silicon steels are generally specified and selected on the basis of allowable core loss in watts/lb.

The grades are called out, in increasing order of core loss by M numbers, such as M19, M27, M36 or M43, with each grade specifying a maximum core loss. (Note that this means that material can be substituted up , as M19 for M36, but not vice versa.) The higher M numbers (and thus higher core losses) are progressively lower cost, although only a few percent is saved with each step down in performance. M19 is probably the most common grade for motion control products, as it offers nearly the lowest core loss in this class of material, with only a small cost impact, particularly in low to medium production quantities. In addition to grade, there are a number of other decisions to make regarding silicon steels. These are:

- Semi vs. Fully processed material

- Annealing after stamping

- Material Thickness

- Surface insulation

Fully processed material is simply material which has been annealed to optimum properties at the steel mill. Semi processed material always requires annealing after stamping in order to remove excess carbon as well as to stress relieve. The better grades of silicon steel are always supplied fully processed while semi processed is available only in grades M43 and worse. The designer considering semi processed M43 should evaluate Low Carbon Steel which may provide equivalent performance at lower cost.

Even though annealed at the mill, fully processed material may require further stress relief anneal after stamping. The stresses introduced during punching degrade the material properties around the edges of the lamination, and must be removed to obtain maximum performance. This is particularly true for parts with narrow sections, or where very high flux density is required. In one instance, a tachometer manufacturer was able to reduce the stack height in his product by 10% by annealing after stamping. The annealing cycle requires a temperature of 1350-1450 F in a non oxidizing, non carburizing atmosphere. Endothermic, nitrogen, and vacuum atmospheres all work well. The selection of lamination thickness is a fairly straightforward trade off of core loss versus cost. Thinner laminations exhibit lower losses (particularly as frequency increases), but thinner material is more expensive initially, and more laminations are required for a given stack height. The most common thicknesses are .014 in., .0185 in., and .025 in. (29 Gauge, 26 Gauge, and 24 Gauge, respectively.) These thicknesses are supplemented by thin electrical steels, available in .002, .004, and .007 in. thick. Thin electrical steels are available in one grade (Equivalent to M19) and are made by re-rolling standard silicon steel. Due to substantially higher material cost, thin electrical steel is used primarily for high performance and high frequency applications. In order to gain full advantage from a laminated core, the laminations must be insulated from one another. The simplest way to do this is to specify a surface insulation on the raw material. Silicon steels are available with several types of insulation:

- –C-0:

Also called bare, or oxide coated. This is a thin, tightly adherent oxide coating put on the material at the steel mill, or during the annealing process after stamping. This is the lowest cost insulation, but offers little resistance. - –C-3:

Enamel or varnish coating which offers excellent insulation, but parts so coated cannot be annealed after stamping. - –C-4:

An inorganic coating providing higher resistance than C-0, but which will withstand annealing temperatures. - –C-5:

An improved inorganic coating similar to C-4 but with significantly higher resistance. It withstands annealing well in most cases. This is probably the best choice for most performance sensitive applications. The main drawback to C-5 is an increase in tool wear due to abrasiveness.

Nickel Alloys

When we talk about nickel alloys for rotating electrical equipment, we are talking about two alloys, 49% Ni and 80% Ni, with the balance being primarily pure iron in both cases. These motor lamination alloys are chosen for their very high permeability at low to moderate inductions, and for their low core losses. These characteristics make them ideal not only for motors, but particularly for synchros and resolvers.

These materials are significantly higher in cost than silicon steels, and require careful handling to achieve acceptable properties. The 80% nickel alloy is not suitable for high flux densities (Above about 8000 Gauss) due to saturation at that level. The difference between the two alloys is one of degree rather than type, with the 80% Ni having the same advantages as 49%, only more so.

Nickel alloys require a very careful annealing cycle in order to be useful. The required temperature is over 2000 F, and special precautions must be taken to avoid welding the motor laminations together at that temperature. Usually, Aluminum oxide powder is placed between the laminations, or a magnesium oxide solution can be applied to the parts and allowed to dry. In addition, a very pure atmosphere of dry hydrogen is required. Finally, as if that wasn’t enough, the properties of the annealed parts are very sensitive to stress. Bending or even dropping the laminations can completely destroy their value. For this reason, the flatness of the finished part must be controlled closely to avoid stresses when put into stacks.

Surface insulation for nickel alloy laminations must be added as part of the annealing process. Most commonly, air or steam is introduced into the retort at about 900 F, which produces a blue- black film integral with the surface of the part. Insulation is not available on the raw material as is the case for silicon steel. The previous discussion is not meant to imply that users of the nickel alloys should expect problems, and in fact the material is used extensively in certain applications. Due to the high value of the finished parts, however, the prospective user of nickel laminations should exercise care in selecting a vendor with experience with nickel alloys.

Cobalt Alloys

Cobalt alloy (Trade Name Hiperco or Vanadium Permundur) laminations are necessary in certain applications, but due to their very high cost must be considered a last resort after examining the other alternatives. Their primary use is in applications requiring the highest possible flux density without saturation. Typical Saturation is as high as 22-23 kG. Most frequently, they find use in airborne and other weight sensitive applications where less metal can be used to carry the required flux. The grade commonly used has 48-50% Cobalt, with the balance iron, and 2% vanadium. It occasionally finds use where its high tensile strength is advantageous, but stress is seldom a primary design criteria for laminations.

Like the nickel alloys, Cobalt alloy requires a very precise annealing after stamping, and must be insulated with an oxide coating. It does not require the high temperatures of nickel, but a dry hydrogen atmosphere is necessary. The parts must be brought to within a narrow temperature and, and if a critical temperature is exceeded, the magnetic properties will be destroyed and the parts must be scrapped. This critical temperature varies with material supplier, but is around 1625 F. The material supplier must be consulted before specifying an annealing cycle. The cooling rate must be closely controlled to get the best results. An oxide coating is usually added as a separate process.

Sinotech can ensure excellent quality motor laminations from China, Taiwan and Korea and is very price competitive in Cold Rolled Motor Lam Steel, Silicon Steel, Nickel Alloy, and Cobalt Alloy laminations. Sinotech has audited, qualified and worked with QS-9000 and ISO certified lamination factories in China, Taiwan and Korea for over 12 years. Sinotech is dedicated to delivering laminations and lamination stacks from China, Taiwan and Korea to you at lower prices but the same quality, service and terms as a domestic supplier.

{This article is copyright Proto Laminations Inc. www.protolam.com and is published with permission.}