ASTM A128 Grade A (UNS J91109) is Manganese steel for abrasive casting applications.

ASTM A128 / A128M – 93(2017) Standard Specification for Steel Castings, Austenitic Manganese

ASTM A128 Grade A Casting Chemical Composition:

Carbon: 1.05-1.35

Manganese: 11.0 min

Silicon: 1.00 max

Phosphorus: 0.070 max

Investment casting ASTM A128 is similar to investment casting other steels, but the heat treatment is far more exacting and difficult. Sinotech begins with your 3-D CAD drawings and uses advanced modeling software to create precision mold designs. The modeling assures uniform heat flow and cooling through strategic placement of gates and gas vents.

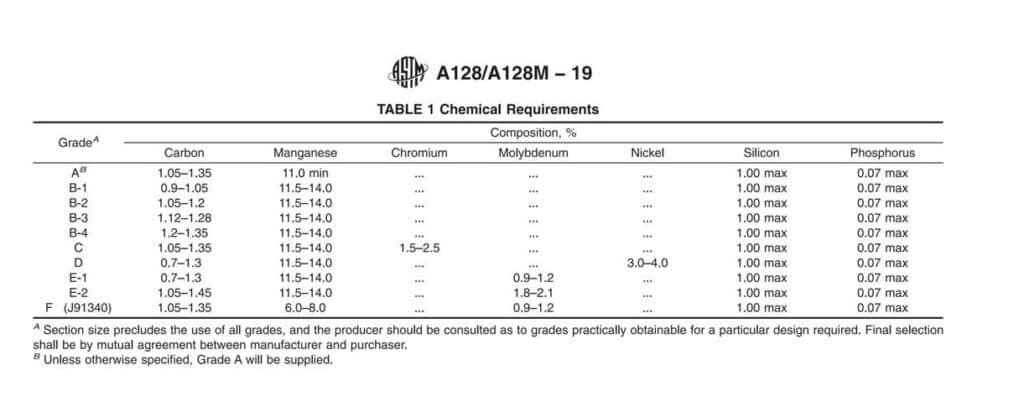

Grades. Here are the available grades of ASTM A128A/A128M – 19

Heat Treatment. Here is a typical heat treat process we use for ASTM A128A investment castings.

First, parts are strung along a steel wire to maintain proper separation for adequate air flow, ensuring uniform heating and cooling. Strings of parts are coiled into a nest to further promote uniform air flow. The parts remain in strings through the heat treating and quenching processes.

Metallurgical Acceptance. Metallurgical acceptance is determined in accordance with the American Society for Testing of Metals Atlas of Microstructures of Industrial Alloys according to agreed upon acceptable microstructures. A section of the part is cut and treated with an etchant used to prepare the specimens.

Sinotech can ensure excellent ASTM A128 investment castings from our Pacific Rim factories and is very price competitive. Sinotech is dedicated to managing your casting project and delivering parts to you at lower prices but with the same quality, service and terms as a domestic supplier. Click on the “Get in Touch” icon at the top of this page to get started.