Ferrite magnets, sometimes referred to as ceramic magnets because of their production process, are the least expensive class of permanent magnet materials. This material became commercially available in the mid 1950s, and has since found its way into countless applications including arc shaped magnets for motors, magnetic chucks, and magnetic tools.

The raw material, iron oxide, for these magnets is mixed with either strontium or barium and milled down to a fine powdered form. The powder is then mixed with a ceramic binder and magnets are produced through a compression or extrusion molding technique that is followed by a sintering process. The nature of the manufacturing process results in a product that frequently contains imperfections such as cracks, porosity, chips, etc. Fortunately, these imperfections rarely interfere with a magnet’s performance.

The raw material, iron oxide, for these magnets is mixed with either strontium or barium and milled down to a fine powdered form. The powder is then mixed with a ceramic binder and magnets are produced through a compression or extrusion molding technique that is followed by a sintering process. The nature of the manufacturing process results in a product that frequently contains imperfections such as cracks, porosity, chips, etc. Fortunately, these imperfections rarely interfere with a magnet’s performance.

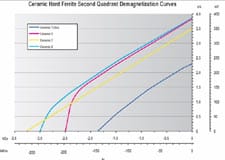

To enhance a ceramic magnet’s performance, the ferrite compound may be biased by a magnetic field during the pressing process. This biasing induces a preferred direction of magnetization within the magnet, significantly reducing its performance in any other orientation. Consequently, ceramic magnets are available in both oriented (anisotropic) and non-oriented (isotropic) grades. Because of its lower magnetic properties, the isotropic grade of ferrite, ceramic 1, is typically utilized where complex magnetization patterns are required, and in process biasing would be cost prohibitive.

Ceramic magnets are inherently brittle, and it is highly recommended that they NOT be utilized as structural elements in any application. Their thermal stability is the poorest of all the magnetic families, but they may be utilized in environments up to 300 Deg C (570 Deg F). The dimensional repeatability of as pressed components is difficult to control, consequently, components requiring tight tolerances necessitate secondary grinding operations to assure conformity.

Sinotech can ensure excellent ceramic magnets from China, Taiwan and Korea and is very price competitive. Sinotech has audited, qualified and worked with QS-9000 and ISO certified magnet factories in China, Taiwan and Korea for over 12 years. Sinotech is dedicated to managing your project on-site and delivering parts to you at lower prices but the same quality, service and terms as a domestic supplier.

Sinotech can ensure excellent ceramic magnets from China, Taiwan and Korea and is very price competitive. Sinotech has audited, qualified and worked with QS-9000 and ISO certified magnet factories in China, Taiwan and Korea for over 12 years. Sinotech is dedicated to managing your project on-site and delivering parts to you at lower prices but the same quality, service and terms as a domestic supplier.