Milling is as fundamental as drilling among powered metal cutting processes.

Milling is versatile for a basic machining process, but because the milling set up has so many degrees of freedom, milling is usually less accurate than turning or grinding unless especially rigid fixturing is implemented.

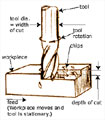

For manual machining, milling is essential to fabricate any object that is not axially symmetric. There is a wide range of different milling machines, ranging from manual light-duty BridgeportsT to huge CNC machines for milling parts hundreds of feet long. Below is illustrated the process at the cutting area.

Milling: Column-and-Knee Manual Mill

Below is illustrated a typical column-and-knee type manual mill. Such manual mills are common in job shops that specialize in parts that are low volume and quickly fabricated. Such job shops are often termed “model shops” because of the prototyping nature of the work.

The parts of the manual mill are separated below. The knee moves up and down the column on guideways in the column. The table can move in x and y on the knee, and the milling head can move up and down.

Sinotech offers an exceptionally wide range of secondary processes that are applied to metals formed in hot or cold processes. Sinotech’ Supplier Quality Engineers determine the availability of the process within the metal forming facility, as well as the quality. If the internal secondary processes do not meet Sinotech standards then the processes are carried out in Sinotech-audited and qualified off-site secondary processing facilities. Sinotech has audited, qualified and worked with QS-9000 and ISO certified secondary processing facilities in China, Taiwan and Korea for over 12 years. Sinotech is dedicated to managing your project on-site and delivering parts to you at lower prices but the same quality, service and terms as a domestic supplier.